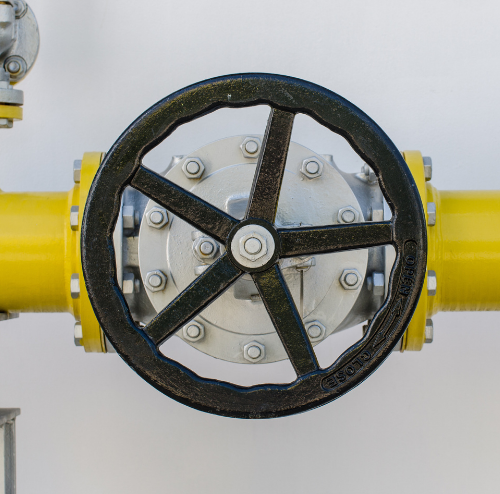

The Global Valve Remote Control System market is expected to see growth in the next few years. According to Yahoo Finance: Global valve remote control system market is expected to grow at a significant rate in the forecast period, 2022-2026. The rising population around the globe is generating the need for more energy generation and transmission. The increase in power generation by the installation of new plants and the growing adoption of green energy is expected to influence the demand for global valve remote control system market. The surge in the investment for the development of the petrochemical and chemical

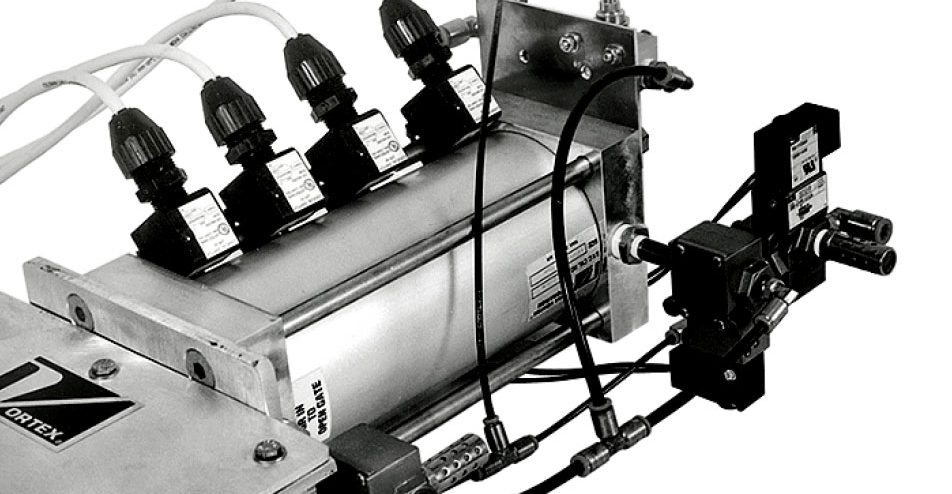

Curious what the basic types of pneumatic circuits are? According to Hydraulics & Pneumatics: The following four pneumatic circuits can be used for air preparation, double-acting cylinders, continuous cycling and hand control applications. They can also be subsystems in larger circuits. Air Preparation Before compressed air is used in a pneumatic device, it must be properly prepared so that it does not damage components. Here is a schematic (below) for a pneumatic device that prepares compressed air coming from a single source. Putting the manual shut-off valve or pneumatic isolation/lockout valve first makes it easier to maintain the FRL and

The control valve market is expected to see growth in coming years. According to EIN Newswire: Allied Market Research recently published a report on the global control valve market. The report offers an in-depth study of the global Building and construction plastic market coupled with the study of dynamic driving factors, constraints, challenges, and opportunities. The report provides a comprehensive analysis regarding leading market players and their business strategies to aid shareholders, new market entrants, and stakeholders and make informed business decisions. The report analyzes the global control valve market on the basis of type, operation, application, and region. The

Looking to optimize fluid dispensing in your auto assembly operation? According to Today’s Motor Vehicles: Automotive component manufacturers face production challenges. Among the most vital is maintaining a high level of product quality, supported by consistent production throughput with systems that ensure profitability. A key function is assembly, especially as the demand for more automated sensing and control devices, connectivity, infotainment, and green initiatives like electric vehicles, continue to push the need for more complex assembly requirements. The need to manufacture more complex assemblies poses challenges for process engineers in their manufacturing and assembly functions. Automotive component manufacturers are mandated

According to Control Global: Greg: I became sensitized to the need for control valves to respond to small signal changes during my many decades of doing pH applications, as described in my ISA book, Advanced pH Measurement and Control, Third Edition. A resolution limit of 0.1% for even the best control valves could translate to a 2 to 12 pH oscillation in a strong acid and strong base neutralization. Since resolution limits are in percent of valve capacity, this translated to an increasing need for multiple stages of neutralization, with the first stage setpoint on the flattest part of the titration

Looking to control your slide gate pneumatically? According to Powder & Bulk Solids: In most bulk powder handling applications, slide gates are predominantly used to either completely shut off or completely open the flow of material. In some instances, it may become necessary to limit the amount of material that is allowed to pass through the gate. When controlling the flow of dry bulk solid materials there are varying controls that can be used to meter the volume and flow rate. Flow controls are components that can be added to a pneumatic actuator to assist in controlling material flow. Pneumatic

There are benefits to using a digital valve positioner for your next application. According to AZO Materials: The article will then look at valve types very briefly before focusing on digital positioners. It will examine the expectations that the user should have with regards to digital positioners, for example, whether they are an individual in the engineering team that will have to spec out positioners or an end-user. A number of considerations for selecting a good digital positioner will also be explored, looking at what potential buyers should be looking for, features that would be beneficial in the longer term and